Table of Contents

Potent, rigid, limpid plastic accessible in a number of good colors

Estimated reading time: 6 minutes

Table of contents

What is an Acrylic Sheet?

An Acrylic sheet is a thermoplastic which signifies that it can be heated and molded into some shapes. It consists of 2 parts:

- Acrylic Acid

- Methyl Methacrylate

Acrylic is also known to be the clearest material and gives a transparency rate of 93%.

The acrylic sheet shows glass-like qualities – clarity, beams, and transparency. The acrylic sheet weighs half the weight and is many times more effective than the resistance effect of glass. Acrylic sheet also called Acrylic Glass, Plexiglas, and Lucite is very useful and transparent. It is easy to assemble and bonds well with glues, pasters, bonding agents, and solvents.

Acrylic Properties and Material Options

The Acrylic sheet’s length, width, thickness, and diameter tolerances differ by dimension, model, producer, and grade. The Custom sizes and colors of acrylic sheets are also available upon request. There are several properties and material options given in the market for the same and some of them are:

- Cast Acrylic Sheet has better chemical resistance and premium machining traits than other materials like Extruded Acrylic. It is available in paper and film masks.

- Extruded Acrylic sheets can be produced to any length, which results in cost savings since yield loss will be decreased when pieces are cut from custom-sized sheets. It is best to thermoform and easiest to bond well using solvent cement.

- Acrylic for Architectural Applications- The clarity, featherweight, impact resistance, and weather resistance of Acrylic makes it a preferred choice for architectural applications. Acrylic sheet is utilized in almost everything from windows and wall partitions to lighting fixtures and awnings.

- Acrylic for Transportation Applications– Acrylic is utilized throughout the transportation industry in instrument panels, windows, windshields, and mirrors.

- AMGARD™ Acrylic for Safety Shields– It is a transparent sheet that is formulated with a silver ion antimicrobial agent that helps protect the sheet surface against the expansion of microorganisms like microbes, fungi, rusts, mold-mildew that cause stains and odors.

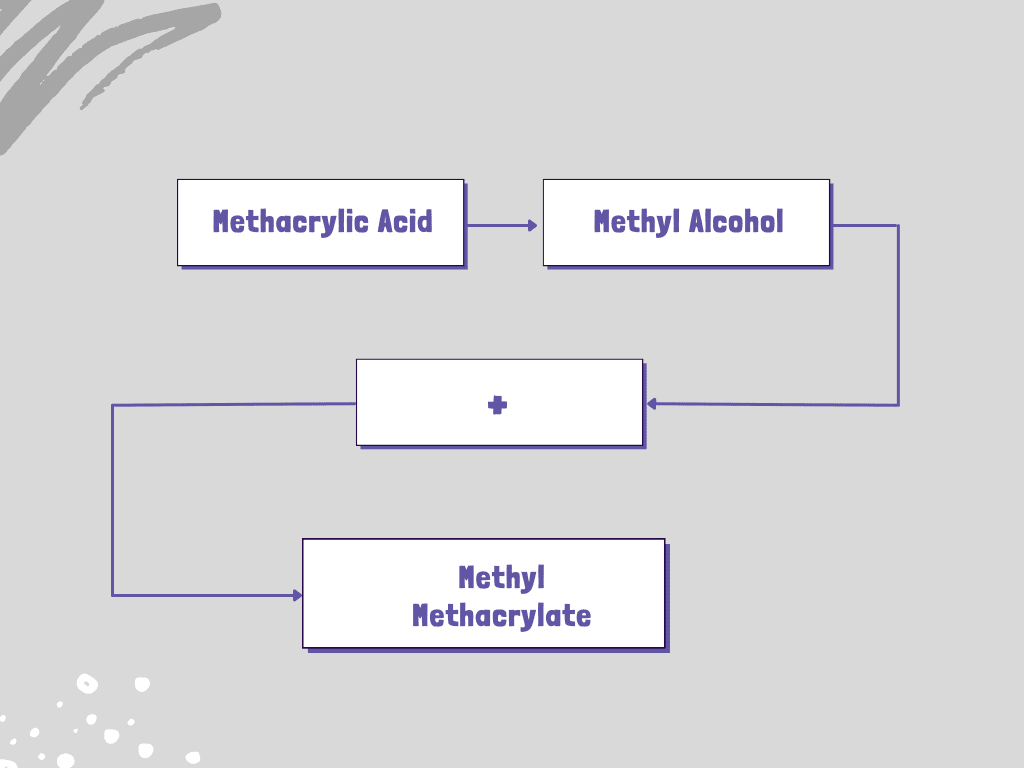

Background of Acrylic Plastic

The foremost common acrylic sheet is poly methyl methacrylate (PMMA). Acrylic Acid was first prepared in 1843. Methacrylic acid which is a derivative of propenoic acid was prepared in 1865.

The German Chemists Fittig and Paul in 1877 had discovered the Polymerization Process to turn methyl methacrylate into polymethyl methacrylate.

The Chemical representation for this material is CH2 = C(CH3).

The process was not used until 1936 to generate sheets of acrylic safety glass commercially. During World War II, acrylic sheets were used for periscope ports on submarines and windshields

Acrylic Sheets for Soundproofing

These sheets are accessible in a variety of thicknesses and can be easily cut off to any size with a knife or scissors. This is the reason that you can easily use acrylic sheets for soundproofing.

Before understanding how to use the Acrylic Sheets for soundproofing, do get to know the basic principles that are applied to these sheets:

- Mass: Sound waves transfer by way of stable mediums by causing vibration. The more mass the strong medium has, the tougher it is to move, thus reducing the quantity of vibration and sound that’s transferred.

- Absorption: Plexiglass is a soft medium that can effectively resist the energy of a sound wave by absorption.

- Damping: Damping is about reducing resonance. Resonance is the ringing sound you hear when you tap on one object like a glass with any metal. Plexiglass is not very resonant since it is soft. It will not ring the way the glass will when tapped on with any metal product, so it’s the better choice when it comes to damping.

Installing Acrylic Sheet

Now, let us understand how to use Acrylic sheets as a soundproofing product. You can easily use these sheets on the inner side of your window or wherever you want to make it noise-free.

- It is recommended to use an Acrylic sheet with a thickness of 3/8 to 1/2 to an inch.

- The surface should be properly cleaned and free from dust or dirt before attaching the acrylic sheet to the surface.

- Measure the surface’s size and the sheet’s size should be slightly larger than the size of the surface.

- It is important to leave an air gap in between the sheets (if using multiple) up to 2 and 4 inches.

- Now, apply a Sealer like a Silicone Sealant to resist the passing of sound waves.

- You can also use a screw/nail to attach the sheets to the surface to make sure that it does not fall off.

- After applying the above DIY steps you can see that the noise passing has been reduced or is negligible.

- You can also attach these sheets either to windows or doors made up of glass without removing the glass.

Purchasing Acrylic Sheets

You can purchase an Acrylic Sheet either from online mode or offline mode depending upon how many sheets you require and what sizes and colors you need. It is recommended to search for wholesalers to get the product at reasonable prices whether through online platforms or nearby local vendors/distributors.

Many top brands produce acrylic sheets at the best price per sq. ft. Some of them are:

- The Tilara

- Riya Enterprise

- The Labworld

- Timios Retails and many more.

Online Mode

There are many online sites through which you can purchase and they even offer doorstep delivery of the product.

Offline Mode

You can locate your nearest distributor or supplier to get the product at an affordable and reasonable rate. Some of the best dealers are:

- Crystal Polycast

- ASM Marketing Private Limited

- Mono sign Store

- Universal Plywood

- Jumei Acrylic Manufacturers

Typical Applications for Acrylic Sheet

There are numerous applications in which Acrylic sheets are being used. Such as acrylic Glass windows, sneeze guards, lightning, Aquariums, Picture Frames, Retail Displays, Noise Reduction, Pharmacy Windows, COVID Barriers, protecting sheets for coronavirus testing facilities, office Cabins, etc.

You can also read about:

- Reading or Study Novels – Where does the term come from?

- A Beginner’s Guide on Loans and Loans Types

- Ever wondered What are Insurances? Types, Agreement, Premium, and More.